Welcome, fellow business owner! Are you looking to optimize the efficiency of your supply chain operations? Look no further than ERP systems. These powerful tools are revolutionizing the way companies manage their supply chains, offering a streamlined approach that can help reduce costs and increase productivity. By integrating all of your key business processes into one centralized system, ERP systems can provide real-time insights and data to help you make informed decisions. Say goodbye to manual processes and hello to a more efficient supply chain with the help of ERP systems.

Importance of ERP Systems in Supply Chain Management

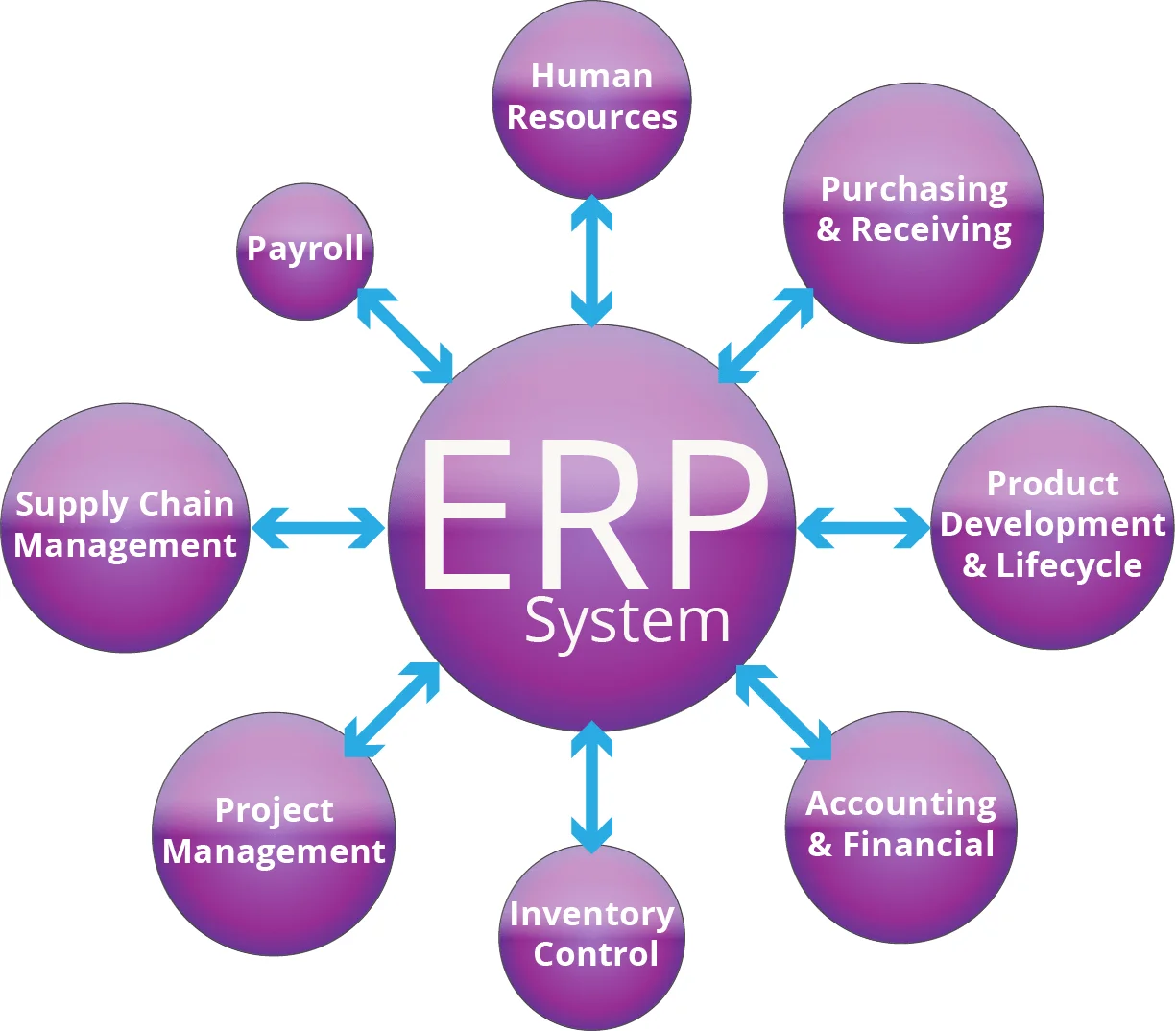

ERP systems play a crucial role in supply chain management by helping businesses streamline their operations, reduce costs, improve efficiency, and enhance visibility across the entire supply chain. These systems are designed to integrate and automate various business processes, including inventory management, order processing, procurement, production planning, and distribution. By providing real-time access to information and data, ERP systems enable companies to make informed decisions and respond quickly to changes in demand, supply, or market conditions.

One of the key benefits of ERP systems in supply chain management is improved efficiency. By automating and standardizing processes, these systems eliminate manual tasks, reduce errors, and ensure consistency in operations. This not only speeds up the flow of goods and information within the supply chain but also minimizes delays, bottlenecks, and disruptions. As a result, companies can fulfill orders more quickly, reduce lead times, and improve customer satisfaction.

Moreover, ERP systems help businesses reduce costs by optimizing inventory levels, minimizing waste, and maximizing resource utilization. By providing real-time visibility into inventory levels, demand forecasts, and production schedules, these systems enable companies to avoid stockouts, overstock situations, and excess inventory. This, in turn, leads to lower carrying costs, reduced storage expenses, and improved cash flow. Additionally, ERP systems help companies identify cost-saving opportunities, negotiate better terms with suppliers, and leverage economies of scale to drive down costs.

Another important aspect of ERP systems in supply chain management is improved collaboration and communication. These systems facilitate seamless communication and data sharing among different departments, business units, and external partners involved in the supply chain. By breaking down silos and fostering collaboration, ERP systems enable companies to work together more effectively, make better decisions, and coordinate activities across the entire value chain. This not only enhances alignment and coordination but also strengthens relationships with suppliers, customers, and other stakeholders.

Furthermore, ERP systems provide valuable insights and analytics that help businesses track performance, measure key performance indicators (KPIs), and identify areas for improvement. By capturing and analyzing data from various sources, these systems enable companies to monitor key metrics, identify trends, and make data-driven decisions. This allows businesses to optimize processes, address inefficiencies, and drive continuous improvement in supply chain operations. Ultimately, ERP systems empower companies to adapt quickly to changing market dynamics, customer preferences, and competitive pressures.

In conclusion, ERP systems play a critical role in modern supply chain management by enabling companies to streamline operations, reduce costs, improve efficiency, and enhance visibility across the entire supply chain. By automating processes, providing real-time information, fostering collaboration, and delivering valuable insights, these systems help businesses navigate the complexities of today’s global marketplace and achieve sustainable competitive advantage.

Key Features of ERP Systems for Supply Chain Optimization

ERP systems play a crucial role in streamlining supply chain management processes. These systems offer various features that can help businesses optimize their supply chain operations and achieve greater efficiency. Here are some key features of ERP systems that are essential for supply chain optimization:

1. Inventory Management: One of the primary functions of ERP systems in supply chain management is inventory management. With real-time tracking of inventory levels, businesses can better manage their stock levels, reduce excess inventory, and prevent stockouts. ERP systems can also automate the procurement process, ensuring that businesses have the right amount of inventory at the right time.

2. Demand Forecasting: Another important feature of ERP systems for supply chain optimization is demand forecasting. By analyzing historical data, market trends, and other factors, ERP systems can help businesses predict future demand more accurately. This enables businesses to plan their production and procurement activities more effectively, ensuring that they can meet customer demand without oversupplying or undersupplying.

Moreover, ERP systems allow businesses to collaborate with suppliers and distributors in real-time, sharing relevant information such as demand forecasts, production schedules, and inventory levels. This collaboration helps in reducing lead times, improving inventory management, and enhancing overall supply chain efficiency.

3. Order Management: ERP systems also offer robust order management capabilities, allowing businesses to manage orders more efficiently. From order processing to fulfillment and shipping, ERP systems track the entire order lifecycle, ensuring that orders are processed accurately and delivered on time. By automating order management processes, businesses can reduce errors, improve order fulfillment rates, and enhance customer satisfaction.

4. Supplier Relationship Management: Effective supplier relationship management is critical for a well-functioning supply chain. ERP systems provide tools for businesses to monitor and evaluate supplier performance, negotiate contracts, and collaborate with suppliers on various business processes. By establishing strong relationships with suppliers, businesses can ensure a stable supply of high-quality materials and components, reducing supply chain risks and disruptions.

5. Analytics and Reporting: ERP systems offer advanced analytics and reporting capabilities that provide businesses with valuable insights into their supply chain operations. By analyzing key performance indicators (KPIs) such as inventory turnover, order fulfillment rates, and supplier performance, businesses can identify areas for improvement and make data-driven decisions to optimize their supply chain. With real-time dashboards and customizable reports, businesses can monitor performance metrics, track progress towards goals, and continuously improve their supply chain processes.

Overall, ERP systems are powerful tools for supply chain optimization, offering a wide range of features that can help businesses streamline their operations, improve efficiency, and achieve greater customer satisfaction. By leveraging the key features of ERP systems discussed above, businesses can transform their supply chain management processes and gain a competitive edge in today’s dynamic business environment.

Benefits of Implementing ERP Systems in Supply Chain Operations

ERP systems play a crucial role in optimizing supply chain operations and improving overall efficiency. Here are some key benefits of implementing ERP systems in supply chain management:

1. Enhanced Visibility and Real-Time Data: ERP systems provide real-time visibility into the supply chain by integrating various processes and departments. This allows companies to track inventory levels, monitor shipments, and analyze data on a centralized platform. With access to up-to-date information, managers can make informed decisions quickly and efficiently, leading to improved productivity and customer satisfaction.

2. Streamlined Processes and Increased Efficiency: By automating manual tasks and standardizing processes, ERP systems help streamline supply chain operations. This can lead to reduced lead times, lower operating costs, and improved resource utilization. With a centralized database and standardized workflows, organizations can eliminate redundancy, minimize errors, and increase overall efficiency in their supply chain.

3. Improved Collaboration and Communication: ERP systems enable seamless communication and collaboration among different stakeholders in the supply chain, including suppliers, distributors, and customers. By providing a centralized platform for sharing information and data, companies can enhance coordination, streamline communication, and build stronger partnerships with their external partners. This improved collaboration leads to better decision-making, faster problem resolution, and enhanced overall supply chain performance.

4. Better Inventory Management and Demand Planning: ERP systems help companies optimize their inventory levels and improve demand forecasting accuracy. By tracking inventory levels in real-time, companies can avoid stockouts, minimize excess inventory, and maintain optimal levels to meet customer demand. Additionally, ERP systems utilize advanced algorithms and data analytics to generate accurate demand forecasts, allowing companies to better align their production, procurement, and distribution processes with market demand.

5. Cost Reduction and Revenue Growth: Implementing ERP systems in supply chain operations can lead to significant cost savings and increased revenue generation. By streamlining processes, reducing errors, and optimizing inventory levels, companies can lower their operating costs and improve their bottom line. Additionally, ERP systems provide companies with valuable insights and data analytics that can help identify new business opportunities, drive innovation, and fuel growth in the long run.

In conclusion, ERP systems offer numerous benefits to companies looking to optimize their supply chain operations. From enhanced visibility and real-time data access to improved collaboration and communication, ERP systems are essential tools for companies looking to improve efficiency, reduce costs, and drive growth in today’s competitive marketplace.

Challenges and Risks of Using ERP Systems in Supply Chain Management

Implementing an ERP system in supply chain management can bring various benefits, such as better visibility, efficiency, and decision-making. However, there are also challenges and risks that organizations need to be aware of when using ERP systems in their supply chain management processes.

One of the main challenges of using ERP systems in supply chain management is the high cost of implementation. Implementing an ERP system can be a costly endeavor, as it requires significant investment in terms of software licenses, hardware, training, and customization. This cost can be a barrier for many organizations, especially smaller ones, who may not have the resources to implement an ERP system.

Another challenge is the complexity of integrating ERP systems with existing systems and processes. Many organizations have legacy systems in place that may not easily integrate with an ERP system. This can lead to issues with data migration, system compatibility, and process alignment. Ensuring a smooth integration of ERP systems with existing systems and processes can be a major challenge for organizations.

One of the risks of using ERP systems in supply chain management is the potential for disruptions in operations. If the ERP system experiences downtime or malfunctions, it can lead to delays in production, shipment, and delivery. This can have a significant impact on the organization’s supply chain performance and customer satisfaction. Organizations need to have contingency plans in place to mitigate the risk of disruptions in their supply chain due to ERP system issues.

Security and data privacy are also major risks associated with using ERP systems in supply chain management. ERP systems store sensitive data related to suppliers, customers, inventory, and financial transactions. If this data is not properly secured, it can be vulnerable to cyber-attacks, data breaches, and unauthorized access. Organizations need to invest in robust cybersecurity measures to protect their ERP systems and data from security threats.

Furthermore, another risk of using ERP systems in supply chain management is the lack of flexibility and scalability. ERP systems are designed to streamline and standardize processes, which can limit the flexibility of organizations to adapt to changing market conditions, customer demands, and business requirements. Additionally, as organizations grow and evolve, they may require additional functionalities or the ability to scale their ERP system to meet new demands. Ensuring that the ERP system is flexible and scalable enough to accommodate changes and growth is essential for long-term success.

In conclusion, while ERP systems offer numerous benefits for supply chain management, there are also challenges and risks that organizations need to address. By proactively identifying and mitigating these challenges and risks, organizations can maximize the value and effectiveness of their ERP systems in supporting their supply chain operations.

Best Practices for Successful Implementation of ERP Systems in Supply Chain Processes

Implementing ERP systems in supply chain processes can be a challenging task, but with the right strategies and best practices, it can lead to significant improvements in efficiency and profitability. Here are some key best practices to consider for a successful implementation:

1. Clearly Define Objectives: Before starting the implementation process, it is important to clearly define the objectives and goals of the ERP system. This will help in setting expectations and ensuring that the system is designed to meet the specific needs of the organization.

2. Involve Key Stakeholders: Involving key stakeholders from different departments in the organization is crucial for the success of the ERP implementation. This will help in gathering valuable insights, addressing potential issues, and ensuring buy-in from all involved parties.

3. Conduct Thorough Training: Proper training of employees at all levels is essential for a successful ERP implementation. This will help in ensuring that all users are proficient in using the system and can maximize its benefits for supply chain management.

4. Customize the System to Fit Your Needs: While off-the-shelf ERP systems offer a wide range of functionalities, it is important to customize the system to fit the specific needs of your supply chain processes. This may involve configuring workflows, reports, and dashboards to align with your unique requirements.

5. Regularly Monitor and Evaluate Performance: Once the ERP system is implemented, it is crucial to regularly monitor and evaluate its performance. This can be done through key performance indicators (KPIs) such as on-time delivery rates, inventory turnover ratios, and order fulfillment times. By analyzing these metrics, organizations can identify areas for improvement and make necessary adjustments to optimize supply chain processes.

By following these best practices for the successful implementation of ERP systems in supply chain processes, organizations can streamline operations, improve visibility, and enhance collaboration across the supply chain. It is important to remember that implementing an ERP system is an ongoing process that requires continuous monitoring and adaptation to meet the changing needs of the business.

Originally posted 2024-02-01 07:13:21.